Cutting Through the Confusion: A Comprehensive Guide to Utility Knife Blades

Utility knives are versatile tools that have become a staple in workshops, home toolboxes, and office desks.

One of the critical reasons for their popularity is the range of utility knife blades available, designed for various cutting tasks and materials.

Understanding the different types of utility knife blades is essential to ensure you have the right edge for your cutting needs.

This comprehensive guide will discuss the various types of utility knife blades, their unique characteristics, and the best applications for each type.

Types of Utility Knife Blades

Standard Blades

Standard utility knife blades, or straight or general-purpose blades, are the most common type of blade in utility knives. These blades feature a straight, slightly curved cutting edge with a sharp point, making them ideal for a wide range of cutting tasks.

Best Applications for Standard Blades

- Cardboard and paper cutting

- Opening packages

- Cutting through plastic and vinyl

- Removing caulking or adhesive

Hook Blades

Hook blades, as their name suggests, have a curved, hook-like shape. This unique design allows the user to make precise cuts without damaging the material beneath the cutting surface. Hook blades are often used in construction and flooring applications.

Best Applications for Hook Blades

- Cutting carpet and linoleum

- Trimming roofing materials

- Slicing through thick fabric or upholstery

- Cutting through rubber or silicone seals

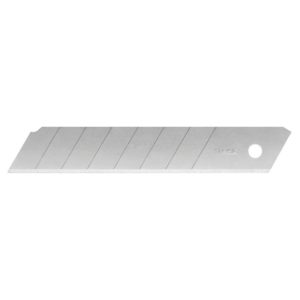

Snap-Off Blades

Snap-off utility knife blades feature multiple scored sections along the length of the blade. An area can be snapped off to reveal a fresh, sharp cutting edge when it becomes dull. This design makes snap-off blades economical, as users can extend the blade’s life before needing a replacement.

Best Applications for Snap-Off Blades

- Cutting cardboard and paper

- Trimming wallpaper or vinyl

- Light-duty construction tasks

- Cutting foam or insulation

Rounded Tip Blades

Rounded-tip utility knife blades have a rounded or blunt tip, reducing the risk of puncturing or damaging the material being cut. This blade type is ideal for applications where precision is more important than penetration.

Best Applications for Rounded Tip Blades

- Cutting vinyl graphics or decals

- Trimming fabric or leather without puncturing

- Opening packages without damaging the contents

- Cutting foam or padding

Serrated Blades

Serrated utility knife blades feature a serrated cutting edge, similar to a saw blade. These blades are designed to handle more challenging materials, such as thicker plastics, rubber, or even metal.

Best Applications for Serrated Blades

- Cutting through heavy-duty plastic or rubber

- Slicing through metal or aluminum sheets

- Trimming automotive hoses or belts

- Cutting through thick rope or cord

Blade Materials

Utility knife blades are typically made from one of two materials: carbon steel or stainless steel. Each material offers unique benefits and drawbacks, depending on your cutting needs.

Carbon Steel Blades

Carbon steel blades are known for their sharpness and durability. These blades can maintain their cutting edge longer than stainless steel, making them ideal for heavy-duty applications. However, carbon steel blades are more susceptible to rust and corrosion, so they may not be the best choice in damp or humid environments.

Stainless Steel Blades

Stainless steel utility knife blades are more resistant to rust and corrosion, making them better suited for use in damp or humid conditions. While not as sharp as carbon steel blades, stainless steel blades still offer excellent cutting performance and durability.

Frequently Asked Questions (FAQs)

How often should I replace my utility knife blade?

The frequency with which you should replace your utility knife blade depends on the type of blade you are using, the materials you are cutting, and the frequency of use. Generally, replace your blade when it becomes dull or damaged to ensure clean, precise cuts and avoid potential injuries.

Can I sharpen my utility knife blade?

Some utility knife blades can be sharpened using a knife sharpener or sharpening stone. However, this process can be time-consuming and may not produce the desired results for all types of blades. In most cases, it is more efficient and cost-effective to replace the edge when it becomes dull.

Are utility knife blades interchangeable?

Many utility knives are designed to accept various blade types, making switching between blades easily depending on your cutting needs. However, some utility knives may only be compatible with specific blade types, so it’s essential to consult your knife’s manufacturer’s guidelines before purchasing replacement blades.

Conclusion:

Understanding the various types of utility knife blades is crucial to ensure you have the right edge for the task at hand.

From standard blades for everyday cutting tasks to specialized blades designed for unique applications, there is a utility knife blade for every cutting need.

By familiarizing yourself with the different blade types, materials, and best applications, you can maximize the versatility of your utility knife and tackle any cutting project with confidence.