Safety cutters are commonly used in many industries where breaking down cardboard boxes is a frequent task.

However, their everyday use can sometimes overshadow their potential hazards.

One way to mitigate these risks and ensure safety is by using box-cutter gloves.

This article explores the importance of these specialized cut-safe gloves in maintaining a safe work environment.

- $139.99This product has multiple variants. The options may be chosen on the product page

- Rated 5.00 out of 5$28.99This product has multiple variants. The options may be chosen on the product page

- Rated 4.67 out of 5$22.99This product has multiple variants. The options may be chosen on the product page

The Risks of Using Box Cutters Without Gloves

Despite their utility, box cutters can cause significant harm if not used properly. Common injuries include lacerations, puncture wounds, and even severe cuts that can damage tendons or muscles.

These injuries can result in significant pain, lost work time, and medical costs.

In some severe cases, these injuries can cause permanent disability, highlighting the critical need for appropriate safety measures, like wearing box-cutter gloves.

The Role of Box-Cutter Gloves in Enhancing Safety

Box-cutter gloves, often crafted from high-strength materials like Kevlar, provide a protective barrier between the sharp blade and the user’s hand.

These materials are engineered to resist cuts and punctures, significantly reducing the risk of injury. By wearing these gloves, workers can handle box cutters more confidently and safely, contributing to a safer work environment.

Legal and Financial Implications of Workplace Safety

Workplace safety isn’t just about preventing injuries; it’s also a legal requirement. Many countries have laws and regulations requiring personal protective equipment, like box-cutter gloves when handling sharp tools.

Non-compliance can lead to hefty fines, lawsuits, and increased insurance premiums. On the other hand, ensuring safety can reduce costs associated with workplace accidents, such as medical expenses, compensation claims, and lost productivity.

Other Benefits of Using Box-Cutter Gloves

In addition to their protective role, box-cutter gloves can improve the user’s grip, enhancing precision when cutting. They also give workers confidence, allowing them to focus more on their tasks and increase productivity.

Moreover, investing in such safety equipment shows a company’s commitment to its employees’ well-being, fostering a positive safety culture.

Choosing the Right Box-Cutter Gloves

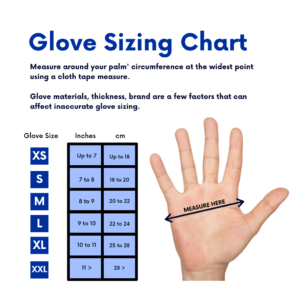

Choosing the right box-cutter gloves involves considering several factors. The ANSI rating is crucial; the highest-rated gloves are certified ANSI A9, whereas the lowest level is A1.

Regardless, the gloves should fit well and be comfortable for long-term wear. They should also be easy to clean and maintain, as dirty or damaged gloves may not provide optimal protection.

Finally, like any safety equipment, box-cutter gloves should be replaced regularly, especially if they show signs of wear or damage.

Conclusion

Box-cutter gloves are a crucial component of workplace safety, offering protection from potentially severe injuries, helping to fulfill legal obligations, and providing other benefits like improved precision and productivity.

Every company that values the safety and well-being of its employees should consider investing in high-quality box-cutter gloves. Remember, a safe workplace is a productive workplace.

Explore the many benefits of purchasing utility knives in bulk—from significant cost savings and enhanced workflow

Explore the many benefits of purchasing utility knives in bulk—from significant cost savings and enhanced workflow

Introducing Slice Ambidextrous Ceramic Scissors As a professional in any industry, having the right tools can